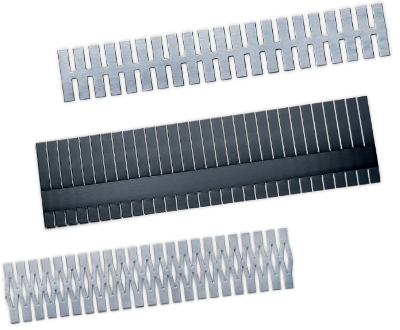

Roll cutting and punching banD

Quality from the startThrough the companies of our ACP Group, we offer more than 400 different variants of punched and roll-cut metal strips. These scaffold tapes are used in a wide variety of sealing systems.

Only high quality raw materials, such as steel, aluminum and stainless steel, from certified suppliers are used for production.

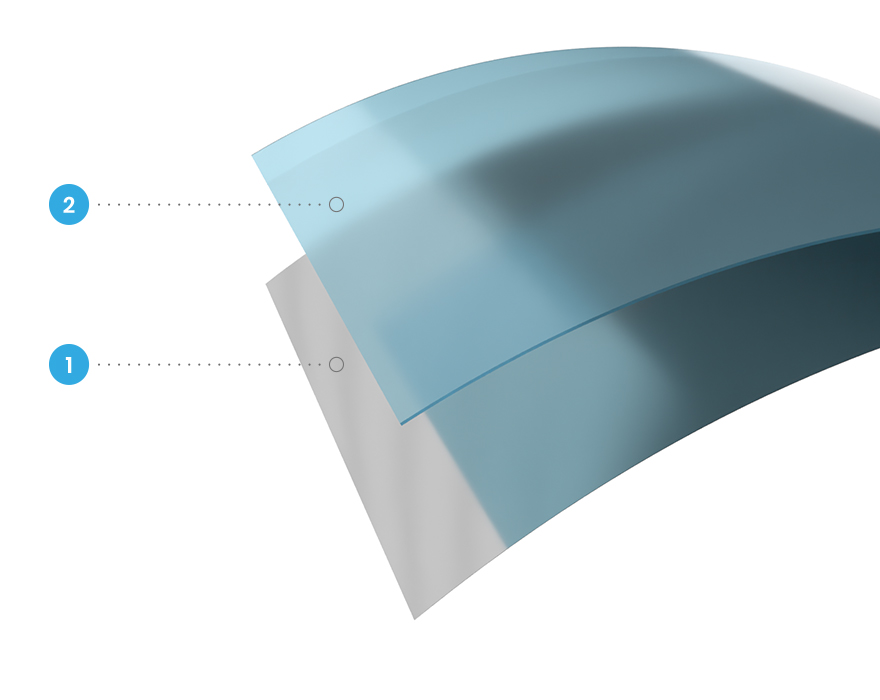

the right coating

Variable applicableYou need additional coating of the metal strips? No problem: Within the HUEHOCO Group there are the specialists who offer a wide range of coating options. From functional to decorative coatings, our customers can choose from a huge range of products.

We also offer suitable adhesion promoters for almost all types of rubber and plastic compounds